Online Coal Analyzer

Online Coal Analyzer is installed over the conveyor belt and provides continuous real-time data of coal parameters, such as calorific value, total ash, moisture and others without sampling. The solution is widely used in coal power plants, coal mines and coal terminals to maximize the use of coal resources or control the quality of produced material.

Applications

• Optimum coal blending to improve boiler combustion and slag reduction

• Stockpile formation and different grade coal production

• Quality control of coal in transport terminals

For more information on the application in the Coal Industry read here.

Main Features

• Stable and accurate analysis of calorific value, total ash, moisture, volatiles matter, carbon content, etc with a high signal/noise ratio.

• Safe and environmentally friendly laser technology with no gamma-ray, neutron or X-ray radiation.

• Meets ASTM D6543-00 (Online Coal Analyzer) measurement standard.

• Explosion Protection Certified design.

• Fully automatic 24/7 operation and SCADA integration.

• Low cost of ownership and maintenance with remote support.

Environmentally and Personal Safe Technology

The Online Coal Analyzer has no gamma-ray, neutron or x-ray radiation. No governmental permissions and licenses are needed for operating, storing and transporting the equipment. No radiation handling personnel is required at premises making it simpler to operate and manage the production or mining process.

Superior Accuracy with High Signal/Noise Ratio

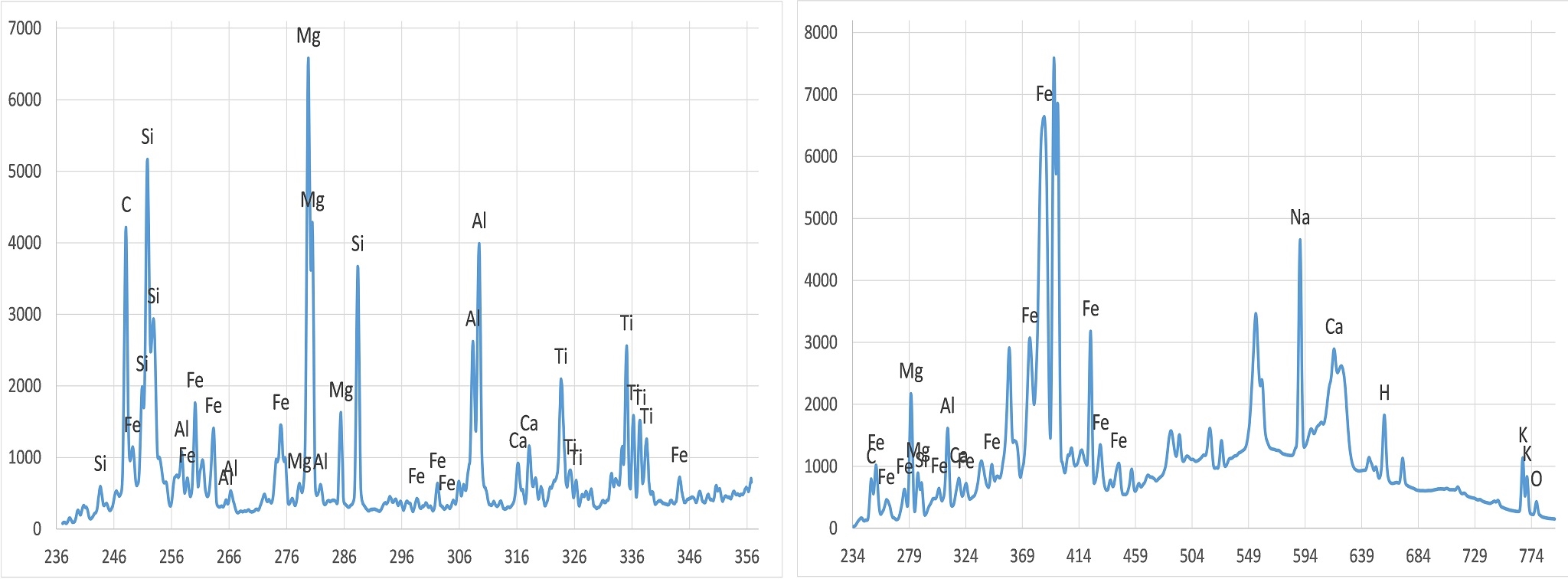

Laser-based (LIBS) technology has clear signal analytical lines of Carbon, ash constituents (Si, Al, Fe, Ti, K, Na, Ca, Mg, etc) and volatiles with high signal/background ration and without interference. Averaged and accumulated chemical composition data is updated every 30 seconds to 5 minutes and can be integrated with any type of automation system.

Long Term Stable Continuous Automatic Operation

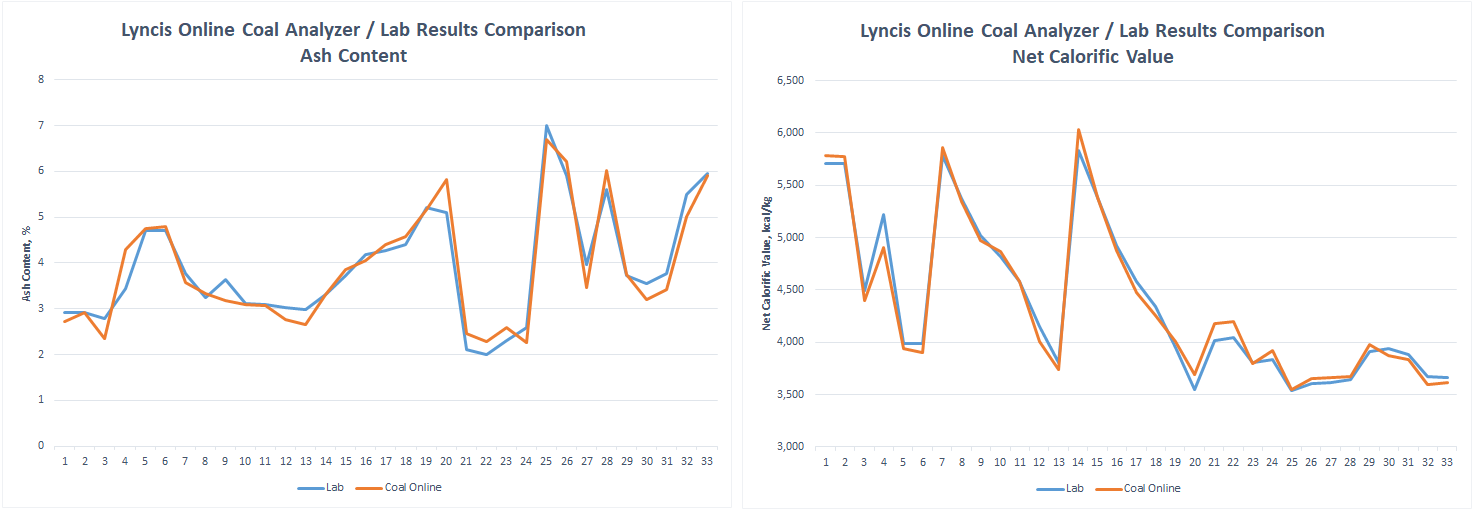

Accurate measurement technology and advanced machine learning algorithms ensure long-lasting and stable online measurements with good correlation with laboratory analysis.

Fully automatic 24/7 operation and integration to customer SCADA provides real-time chemistry of material streams without sampling and sample preparation.

Low Cost of Ownership

The analyzer is a self-contained unit with minimal maintenance requirements. Routine maintenance involves only regular air filter replacement and basic laser window cleaning. No spatial licenses or certificates are required to operate the equipment.

Software

• Performance monitoring and auto-notification if calibration fine-tuning is recommended.

• Easy addition of new sample points to the calibration

database.

• Remote Control and assistance in monitoring and

adjusting machine performance.

• Full SCADA/PLC integration and networking capabilities

allow the analyzers to be integrated. into any Industry 4.0 and the

manufacturing ecosystem.

Advanced Data Analytics

Online elemental analyzers are equipped with data processing modules to monitor and learn the material changes during continuous processes.

To ensure accurate and stable measurements comprehensive calibration and data processing algorithms are build using advanced machine learning and chemometrics technics such as PCA/PCR (Principal Component Analysis/Regression), Neural Networks, SVM (Support-vector machine), PLS (Partial least squares regression), Classification algorithms.