Managing potash recovery and enrichment based on target element concentrations is a routine task. Achieving it with high precision, reliability and repeatability is not easy. A well-equipped laboratory would certainly do that. However, in this case, a process engineer would wait for hours before the lab results are available. Significant changes in chemistry can be missed and it is often too late to correct the production process.

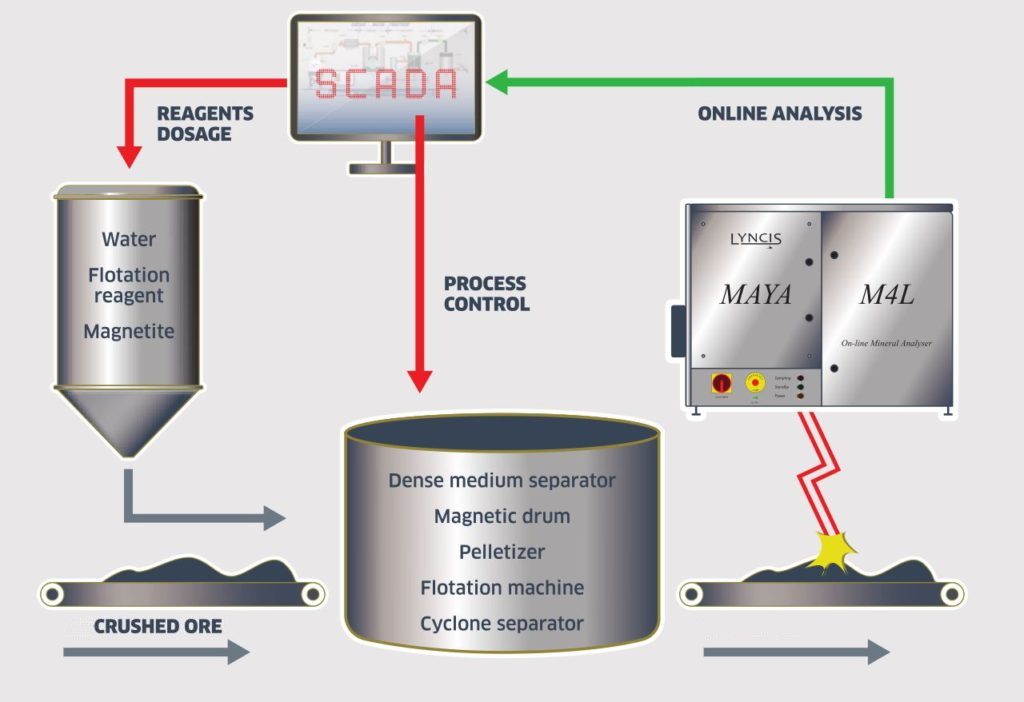

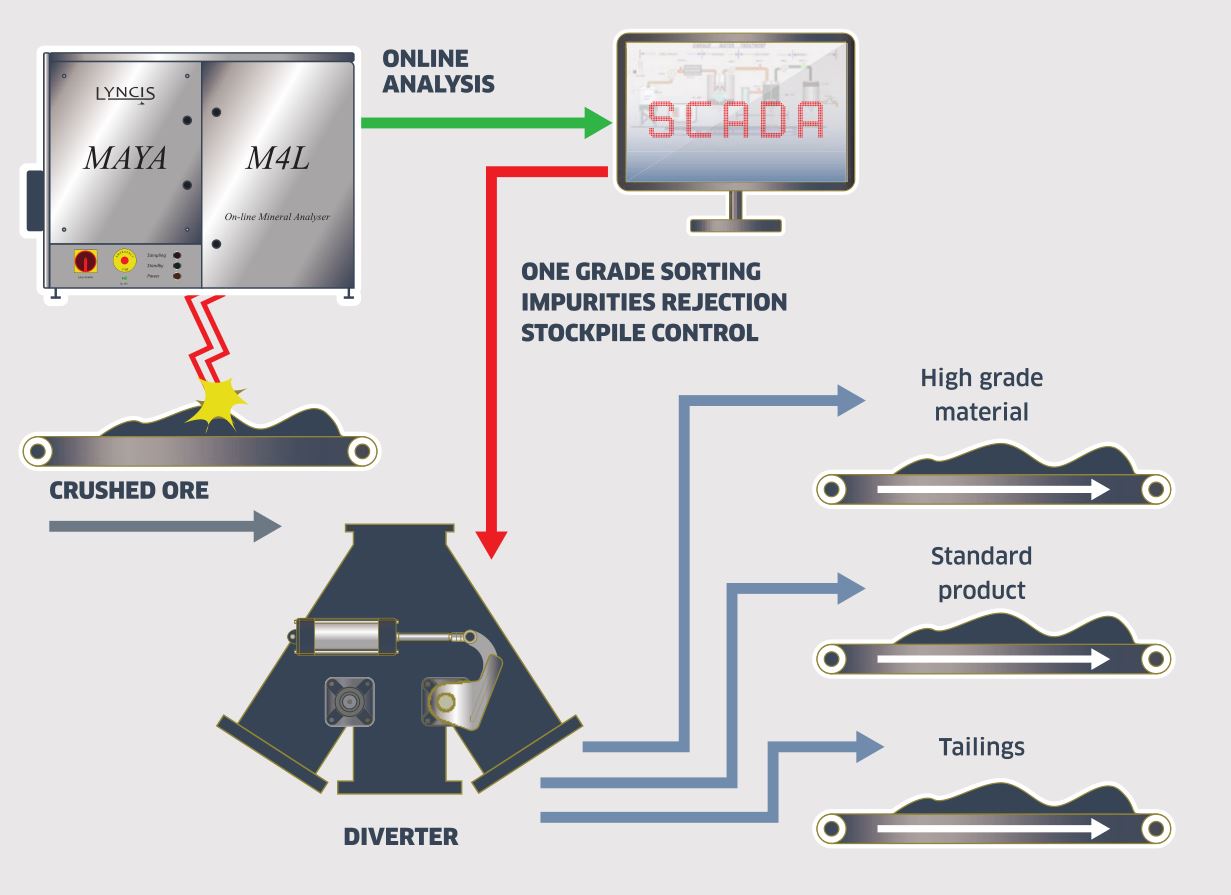

An Online chemical analyzer enables to implement more advanced automated process control. Nothing is missed, the process is adjusted continuously in real-time. This ensures the highest utilization of valuable minerals from raw ore is achieved. The purity of the final product can be adjusted to meet client requirements without the overuse of potassium. Additional revenue is generated not just from additionally recovered potassium, but by saving reagents, water, and energy.

Lyncis radiation-free laser analyzers are successfully used in the analysis of solid and brine materials in the potash industry and deliver solutions for: