Industrial Minerals such as Limestone, Zircon, Graphite, Lithium, Quartz, Cobalt and others are widely used in the variety of industrial and domestic applications.

Lyncis offers online elemental analyzers for industrial minerals process optimization solutions. Real-time chemical analysis of dry materials or slurry flow provides essential data to improve mineral recovery and achieve optimal product quality. The materials can be analyzed on a conveyor belt after/before crushing, grinding and separation process or above slurry flow in flotation and leaching control.

Industrial Minerals Online Analyser

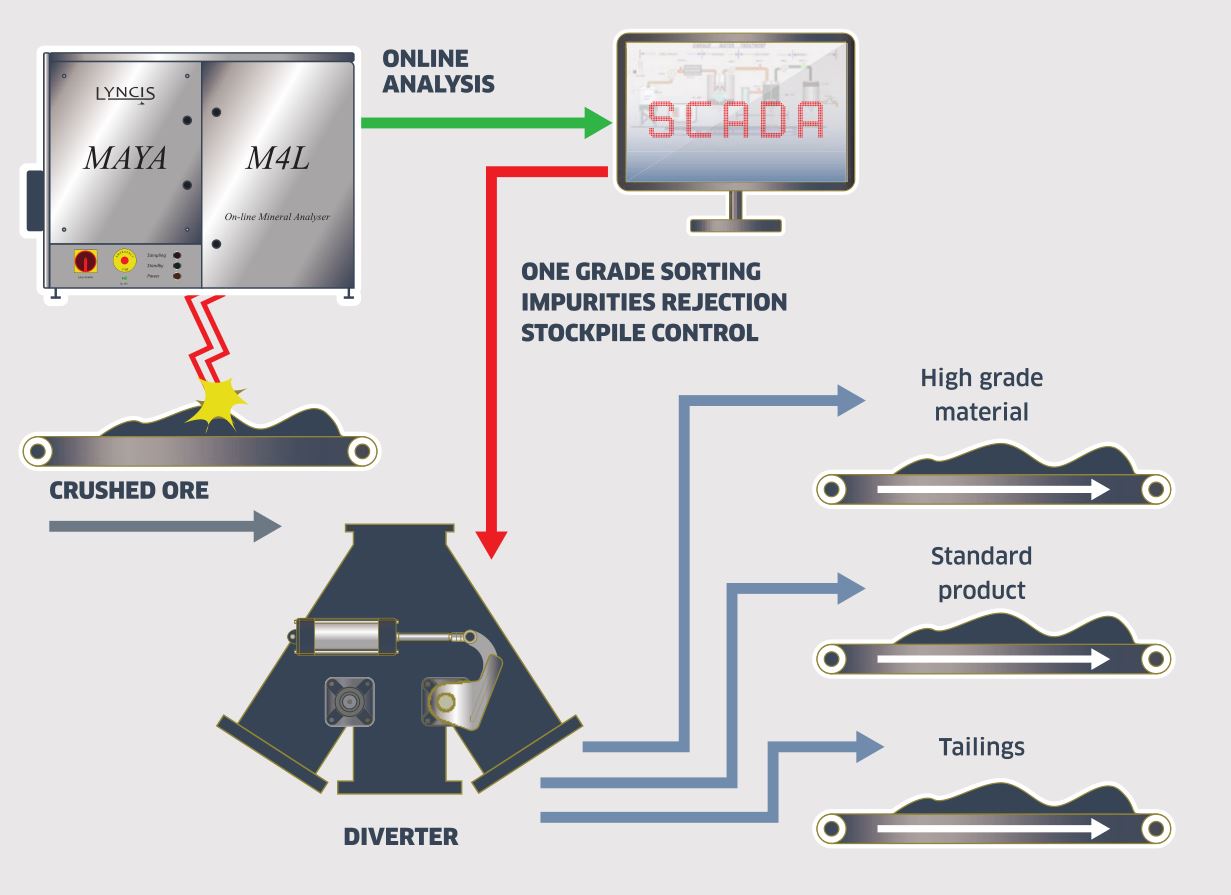

Effective Ore Sorting and Stockpile Control

A mining company forms stockpiles based on the concentration of valuable minerals. Additional revenue is generated from higher grade ore sales.

A processing plant discards waste rock at the mining stage. The plant reduces the consumption of reagents and energy, CO2 emission drops from the calcination process. Less ore needs to be transported and the tailings management becomes easier.

Greenfield projects can benefit from smaller mill size requirements.

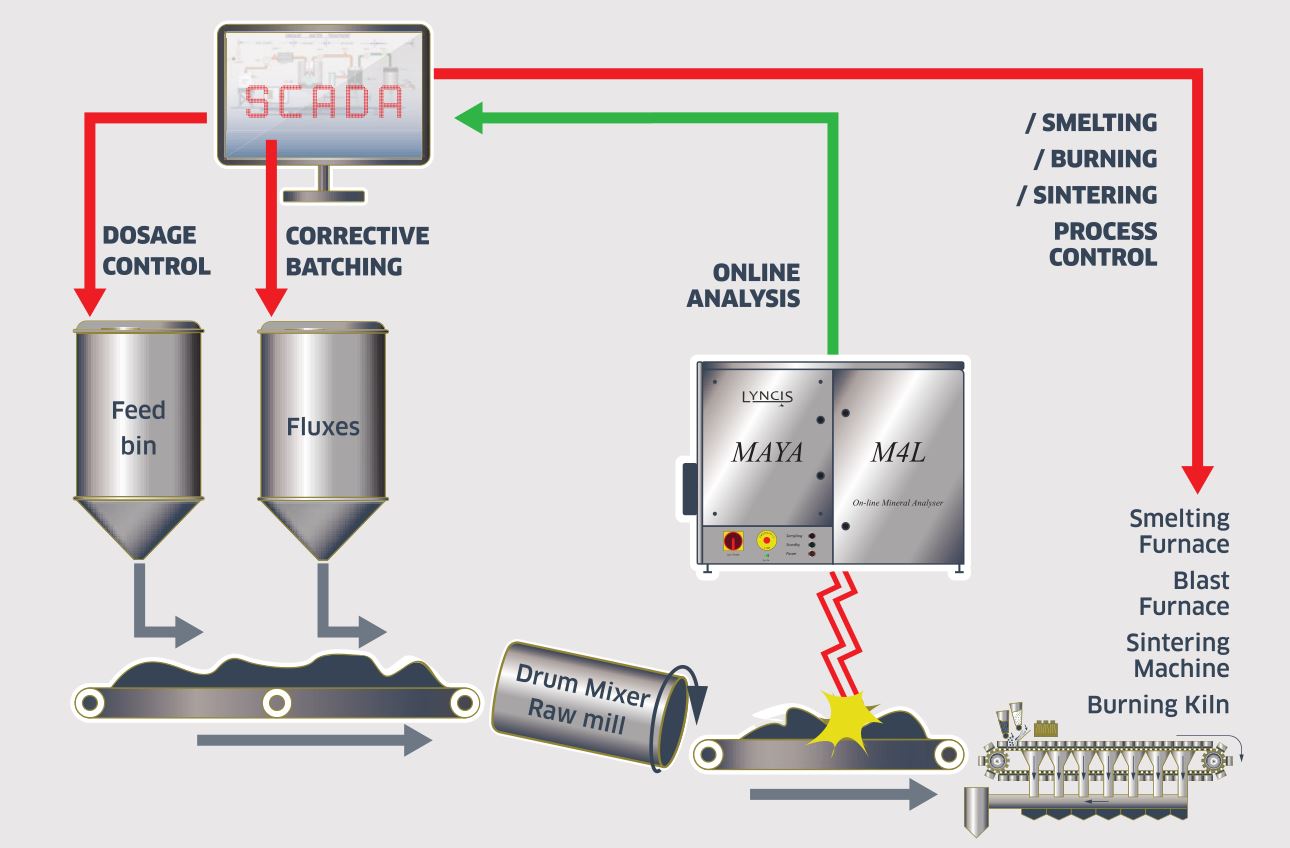

Precise blending control

Online feedback weight feeders control based on real-time chemical composition data makes sure raw mix is always on target with a low standard deviation of essential parameters.

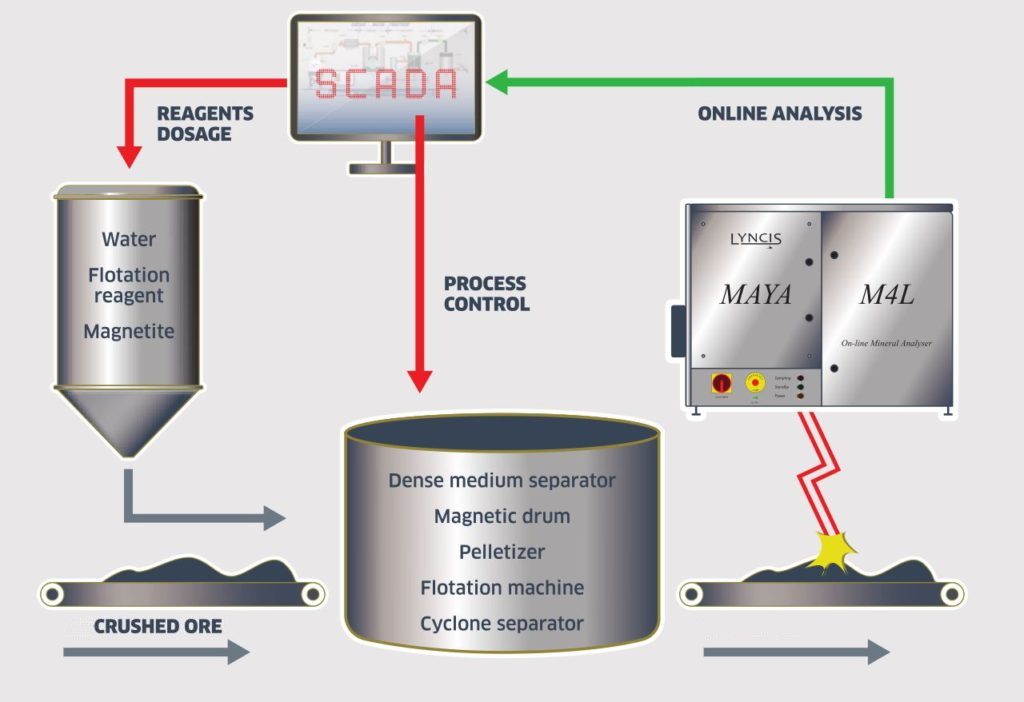

Efective Separation and Concentration Process

Feed-forward or feedback control by monitoring raw ore quality and adjusting the dosage of flotation reagents and water feed to achieve maximum recovery of valuable minerals.

Advantages of Industrial Minerals Online Analyser

• High accuracy and stable analysis of required major elements and impurities of interest

• No regular re-calibration requirements and Low maintenance cost

• Radiation Free, environment and people safe technology

Your Benefits

• Higher recovery of valuable minerals

• Reduced consumption of reagents, water, energy

• Targeted product quality

• Reduced manual labor in sample preparation