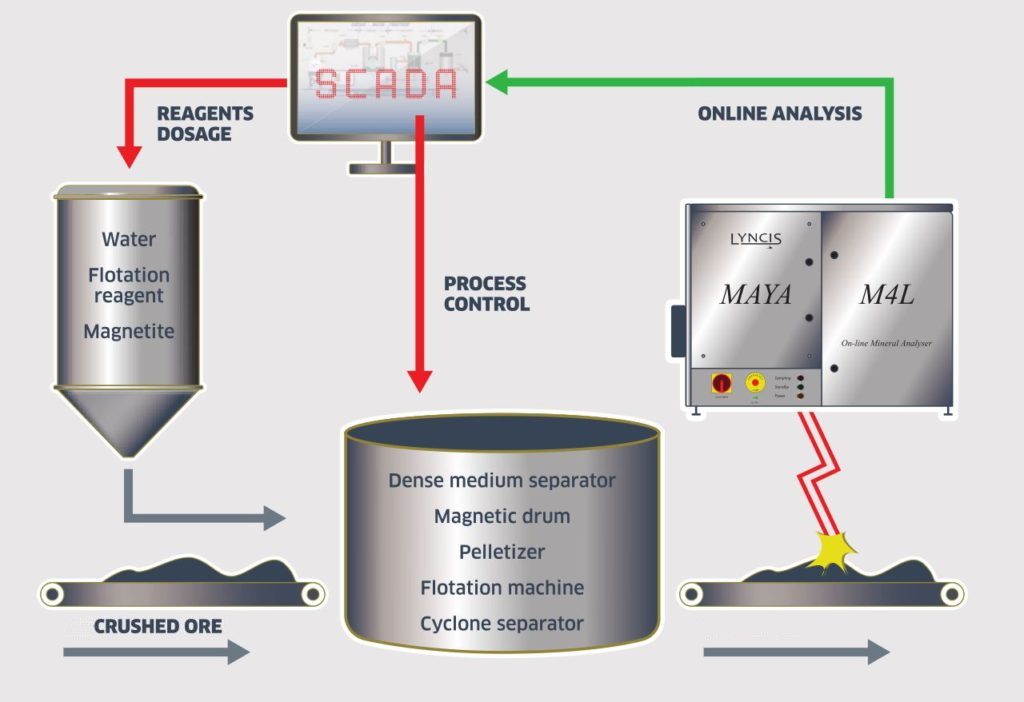

Lyncis LIBS iron ore online analyzer is a radiation-free technology used for process optimization in achieving cost-effective iron production.

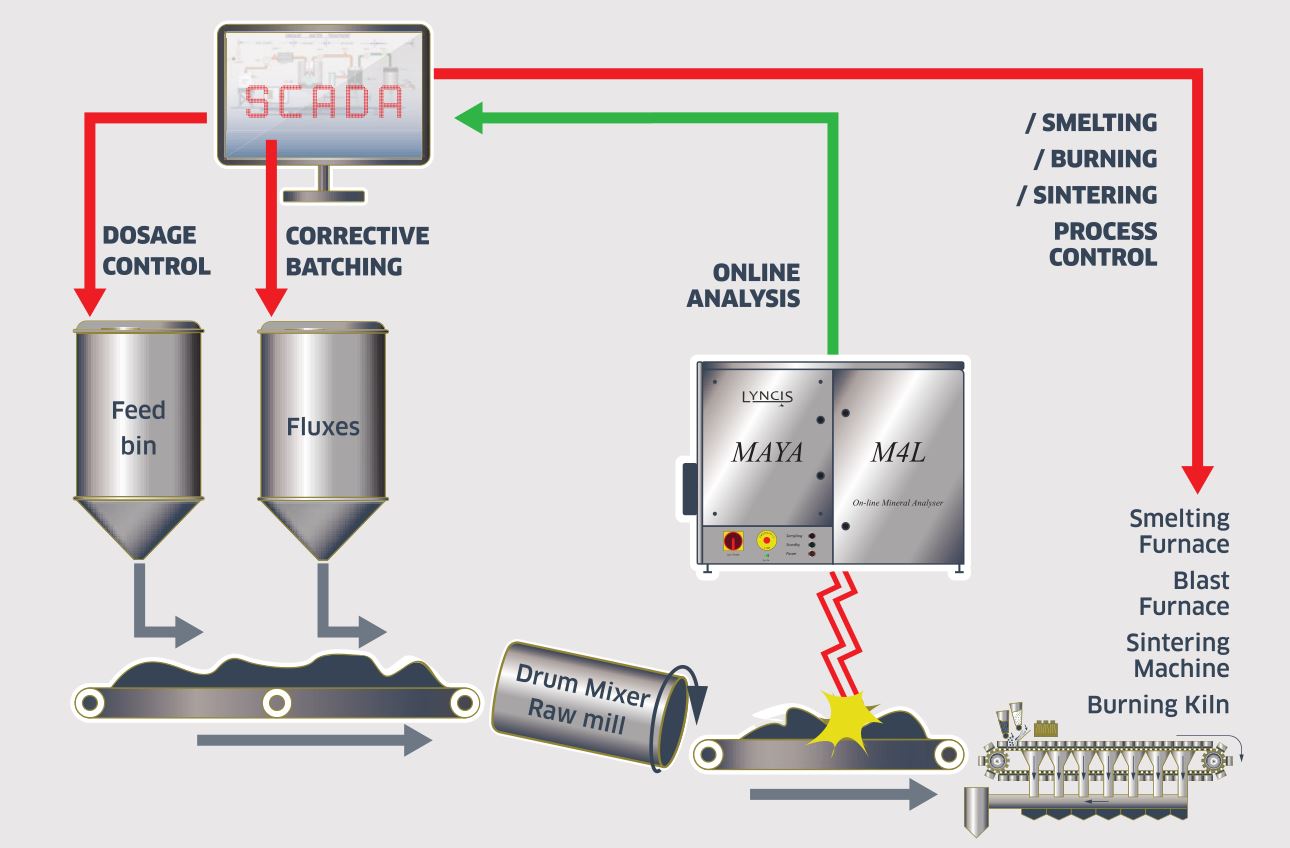

Ironmaking is becoming more and more difficult with growing variations in the chemical composition of raw materials. This leads to lower quality of the final product and significantly increases energy and coke consumption in the production process. An advanced process control system based on real-time chemical composition data of raw materials can solve the problem, allowing to improve product quality, reduce the production cost, and achieve stable blast furnace performance.

We offer advanced: