Online Elemental Analysis of Base and Precious Metals Ore

Lyncis LIBS online elemental analyzer is a radiation-free technology used for process optimization in achieving cost-effective metal production.

Base and precious metals processing is becoming more and more difficult with growing variations in the chemical composition of raw materials. This leads to a lower throughput of the mill and significantly increases mining and beneficiation cost. An advanced process control system based on real-time chemical composition data of raw materials can solve the problem, allowing to improve product quality, reduce the production cost, and achieve stable furnace and smelting operations.

We offer advanced:

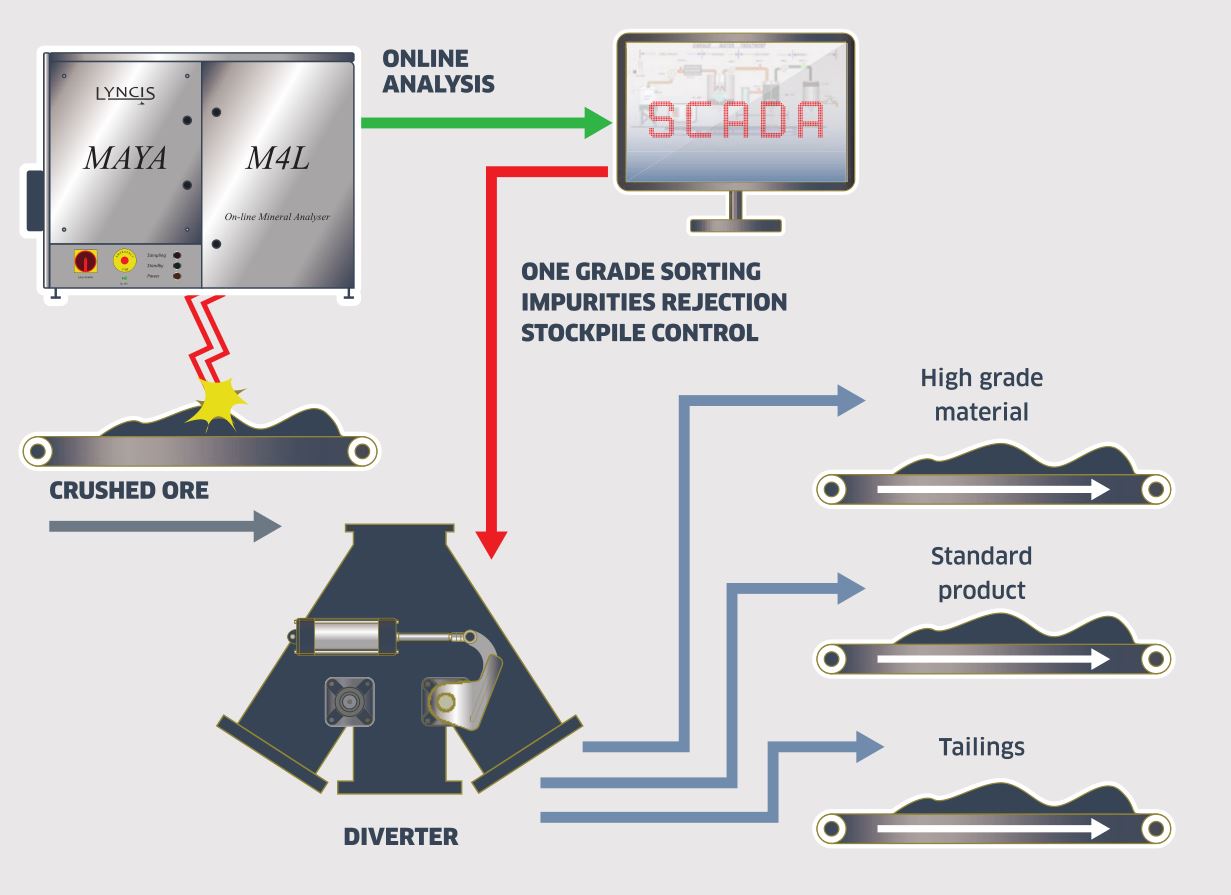

Raw Ore and Concenttrate Quality Control

• Real-time quality control of raw ore to reject off-grade material to minimize beneficiation process cost and improve the mill iron output.

• Stockpile control based on ore grade.

• Conveyor flow diversion to different beneficiation stages based on the concentrations of unwanted elements such as sulfur.

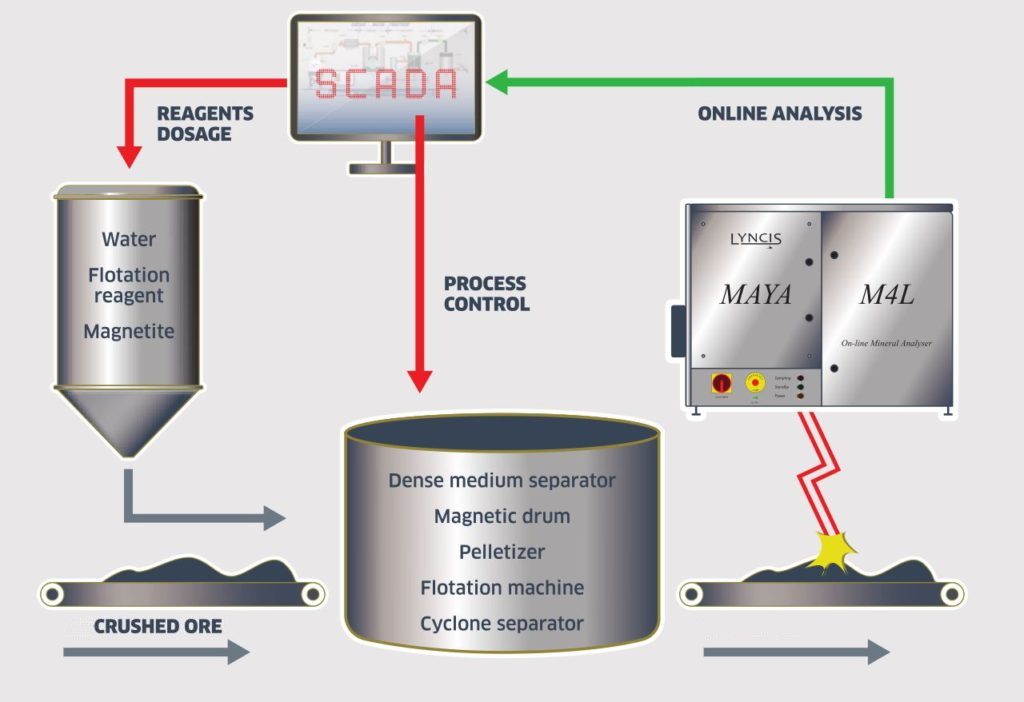

Advanced Beneficiation Process

• Feed-forward or feed-back control by monitoring production quality and adjusting separation technology parameters to ensure the highest mineral recovery. Tailings are monitored to minimize the loss of valuable minerals.

• Online chemical composition data drives beneficiation process decisions in real-time. The optimal dosage of flotation reagents minimizes production cost.

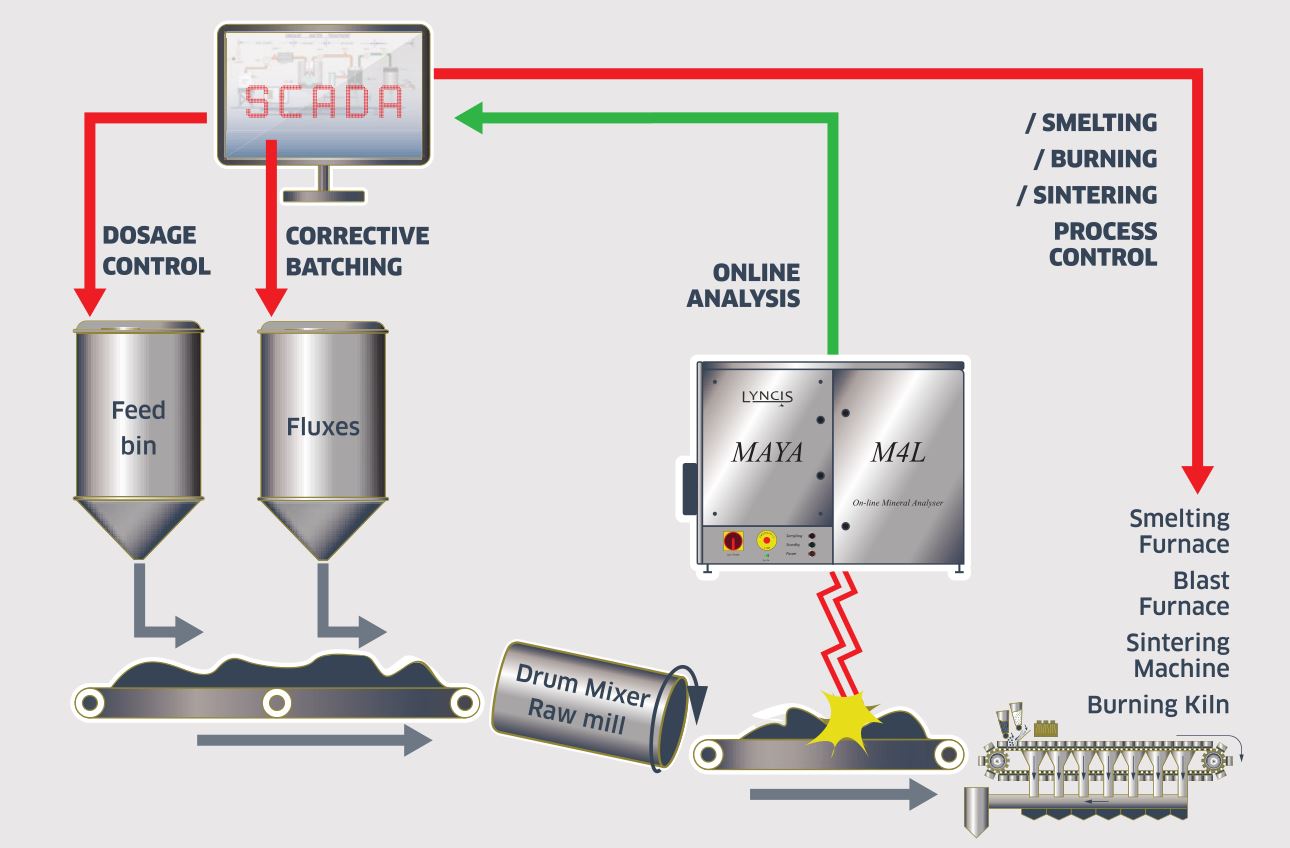

Smelting and Furnance feed control

• Limestone, coke, anode quality control in sintering and furnace operations

• Accurate dosage and mixing of fluxes and additives to get the required raw feed chemistry into burning and smelting operation

Your Benefits

• Increased recovery of valuable minerals

• Improved quality of pellets and concentrate

• Reduced production costs in saving fluxes, reagents and energy

• Increased efficiency and stability of smelting and furnace operation

• Lower content of sulfur and unwanted impurities in the product

Technology Advantages

• High accuracy and low detection limit measurements of all elements of interest simultaneously.

• No regular re-calibration requirements and low operation cost

• Radiation Free, environment and people safe technology